Facilities

Home to more than $2 million in shared equipment and $5 million in faculty lab resources

From 3D printers and CNC manufacturing and welding equipment to a range of ancillary equipment including mechanical testing, microscopy and metrology tools, the School of Manufacturing Systems and Networks is committed to offering its students and community members industry-grade equipment to provide use-inspired learning opportunities.

Much of this equipment is located in the Technology Center at ASU’s Polytechnic campus, home to the Innovation Hub, a 15,000-square-foot, 3D printing research center — the largest additive manufacturing research facility in the southwestern United States partly supported by industry partners such as Honeywell, FANUC America, Rockwell Automation, PADT Inc., Intel Corporation and more. It offers plastic, polymer and metal 3D printing technologies that support a wide range of research, material and process development and educational training. Additional equipment is located in the Simulator Building and Peralta Engineering Studios.

Equipment offerings at the Innovation Hub

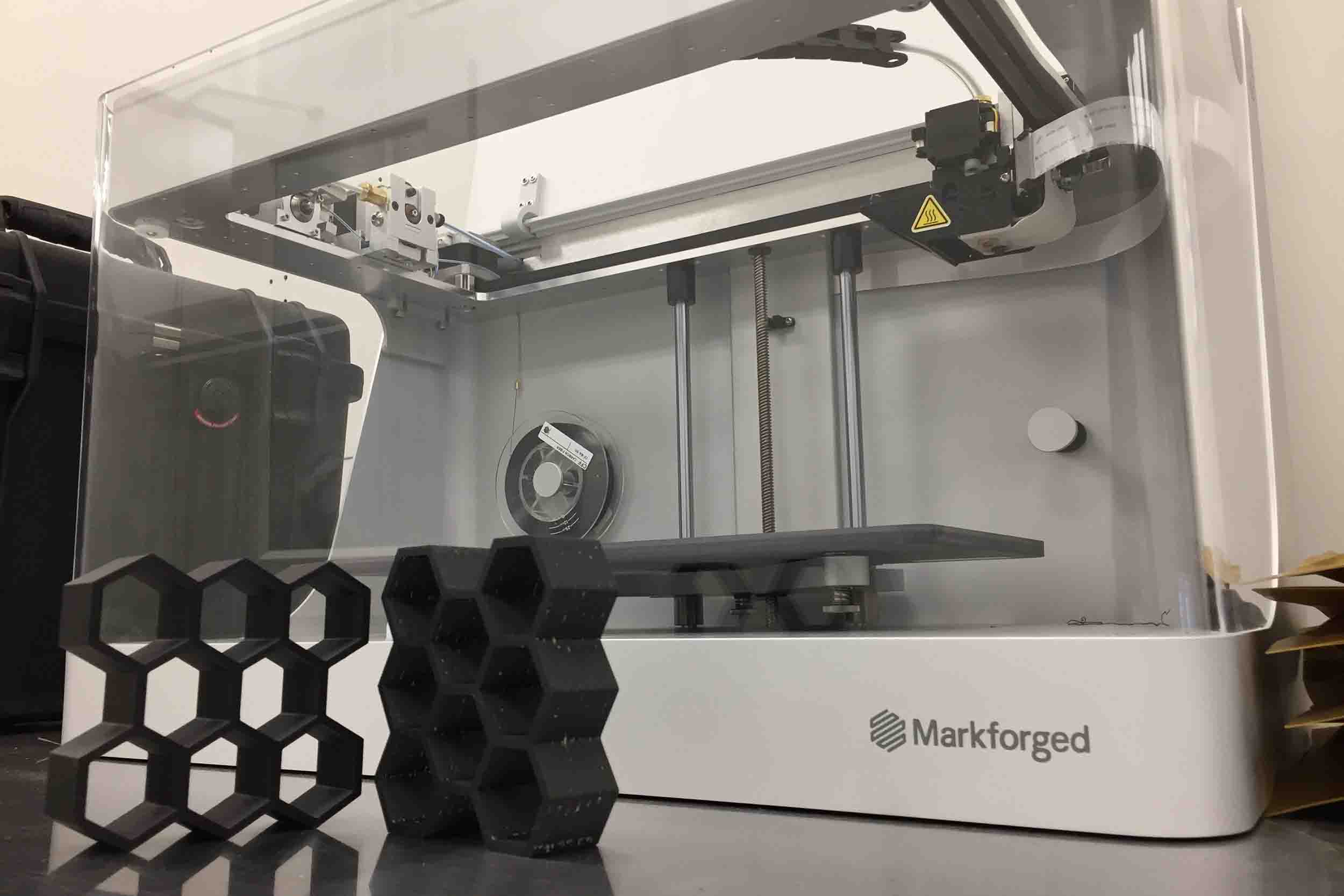

Continuous Fiber 3D printing

Equipment: MarkForged Mark Two

Materials: Onyx, Continuous Carbon Fiber, Kevlar and others on request

Metal Selective Laser Melting (SLM)

Equipment: Concept Laser M2 (400W) and MLab (100W)

Materials: Non-reactive metal alloys (Inconel 718/625, CoCrW, Stainless Steel 316L) and others on request

Selective Laser Sintering (SLS)

Equipment: EOS Formiga P110

Materials: Nylon 12, others on request

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM)

Equipment: Fortus 450mc, Fortus 250mc, Dimension, uPrint, Pruza

Materials: ABS, PLA, Nylon-CF, Nylon, PC, ULTEM 9085, others on request

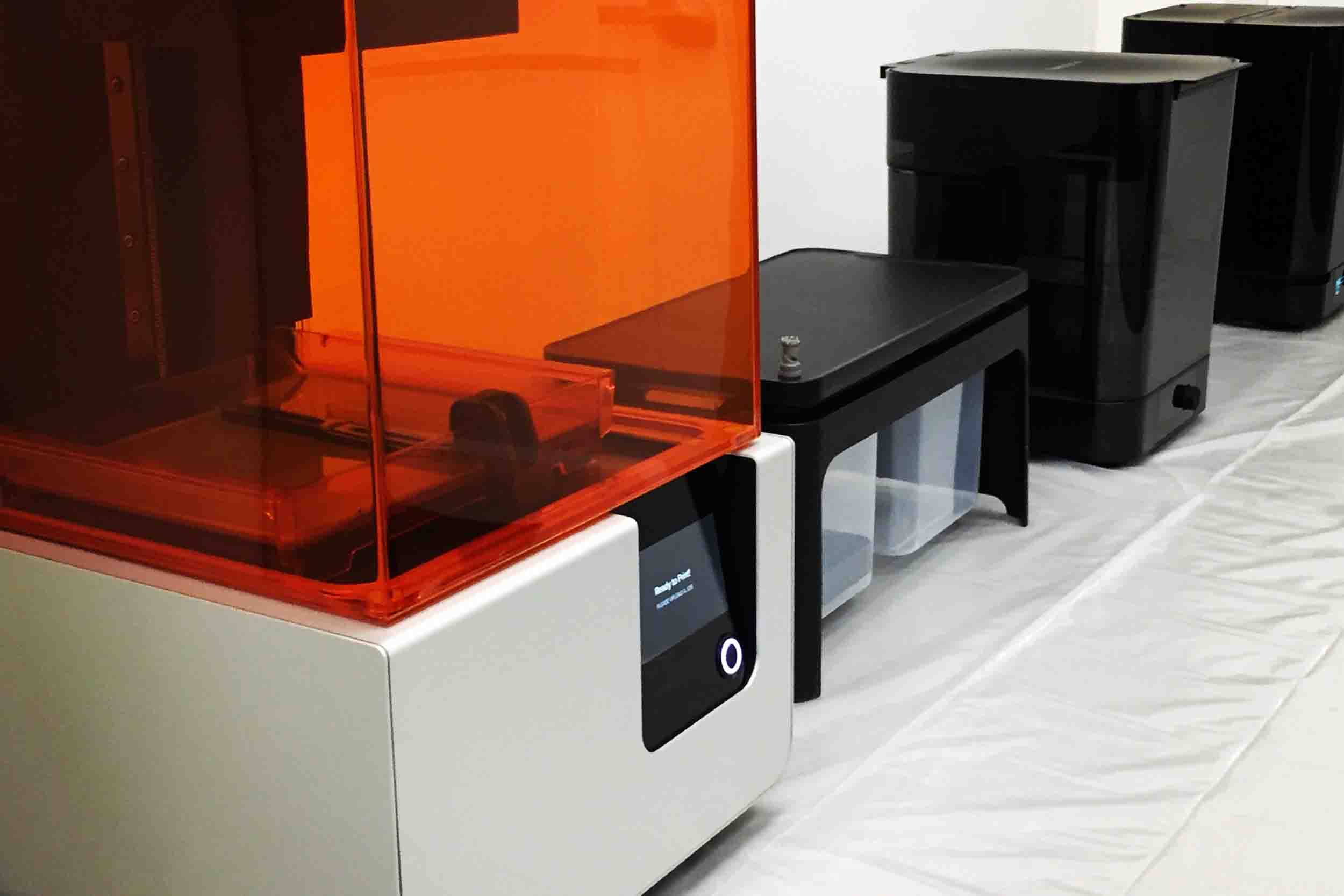

Stereolithography (SLA)

Equipment: FormLabs Form 2

Materials: Standard resins, others by request

Material Jetting

Equipment: Connex 350, Objet 30

Materials: All compatible PolyJet materials

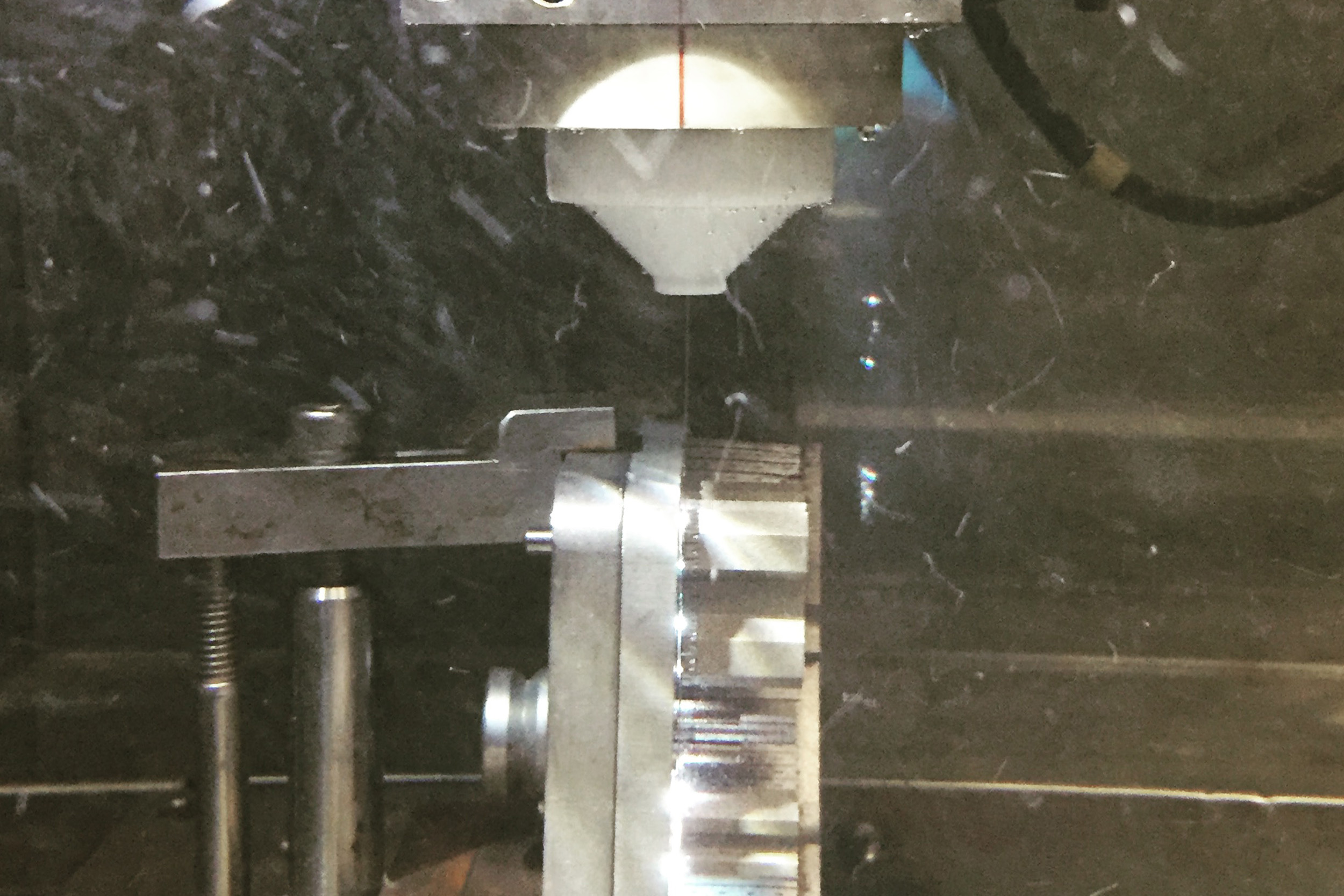

Wire EDM (post-processing)

Equipment: FANUC