Research

Apply to become a Fulton Fellow

The School of Manufacturing Systems and Networks extends several Fulton Fellowships to new students pursuing a doctoral degree in manufacturing or systems engineering. Be considered for four years of funding through this competitive program. All applicants will be considered for the Fulton Fellows program. No separate application is needed.

Today’s manufacturing systems are not simple input-output machines

They demand genuine innovation in the design and implementation of technologies that not only push the boundaries of what’s possible but also integrate diverse engineering disciplines. This involves developing human-machine teams that seamlessly combine expertise from fields like robotics, artificial intelligence, data science and electrical engineering. The aim is to create systems that leverage advanced sensing technologies, high-performance computation, real-time processing and robust networking capabilities. By aligning these technologies, these systems can adapt dynamically and function with optimal performance, achieving breakthroughs in industries ranging from autonomous systems and smart manufacturing to healthcare and beyond.

Our faculty

The quality and expertise of our faculty directly influence student success, shaping both their academic and professional journeys. Faculty members serve as mentors, educators and guides, providing students with the knowledge, skills and critical thinking abilities they need to excel in their fields. Their support often extends beyond the classroom, guiding students through research projects, internships and career decisions.

Research thrusts

Digital manufacturing

Manufacturing processes that are enhanced by data-driven systems to simulate and optimize processes, accelerate production and reduce operating costs through digital collaboration tools across various high-tech industries.

Additive manufacturing

3D printing processes that enable parts to be produced more efficiently and at much faster rates to advance the entire manufacturing ecosystem across the product lifecycle.

Robotics and automation

To keep up with today’s high-tech demands, advanced factories are using robotic platforms and autonomous systems that are capable of carrying out a set of complex tasks at high speeds and in dangerous environments.

Faculty expertise by category

Binil Starly – digital manufacturing, digital factories, Industry 4.0, digital twins, AI in manufacturing

Shenghan Guo – industrial informatics, statistical quality control, interpretable machine learning, big data analytics

Hyunwoong Ko – AI in manufacturing and design, physics-informed machine learning, digitization of factories, cyber-physical systems

Farhad Ameri – semantic AI, digital supply chains, knowledge graphs, ontology

Zhengtao Gan – computational mechanics, real-time process simulation, physics-based AI/ML

Bruno Azeredo – semiconductor manufacturing, metal additive manufacturing, nanomanufacturing

Dhruv Bhate – bio-inspired design, architected cellular materials, metal additive manufacturing

Xiangfan Chen – 3C printing, metamaterials, composites, wearable electronics, photonics, bioprinting

Xiangyang Dong – structural energy storage, sustainable manufacturing, additive manufacturing, multifunctional composites and ceramics, multiscale and multiphysics-informed machine learning modeling, first-principles calculations, molecular dynamics simulations, and finite element methods, materials genome and materials design, laser-aided material processing, processing-microstructure-property relationship

Keng Hsu – polymer additive manufacturing, metal additive manufacturing, solid-state welding

Chao Ma – additive manufacturing, laser manufacturing, metal matrix nanocomposites, porous materials, carbon capture and utilization

Mostafa Yourdkhani – multi-functional composites, robotic additive manufacturing

Daniel Aukes – robotics, design, dynamics, kinematics, mechanism design, manufacturing planning, laminate fabrication techniques, rapid prototyping design for affordability, design for manufacturability

Sangram Redkar – robotics, dynamics and control

Thomas Sugar – human-robot integration, exoskeletons, robotics

Wenlong Zhang – human-robot collaboration, dynamics systems modeling and control, wearable robotics, soft robots, aerial robots

Jerry Gintz – industrial automation, robotics in manufacturing

Troy McDaniel – haptic interfaces, haptic intelligence, sensory augmentation, smart multimedia

Ehsan Dehghan-Niri – acoustic imaging, non-destructive testing, robotic inspection, in-situ quality control

Kevin Nichols – robotics, dynamics and control

Xi Yu – multi-robot systems, autonomy in extreme environments, autonomous blimps and underwater vehicles

Meet the MSN faculty

Research centers and facilities

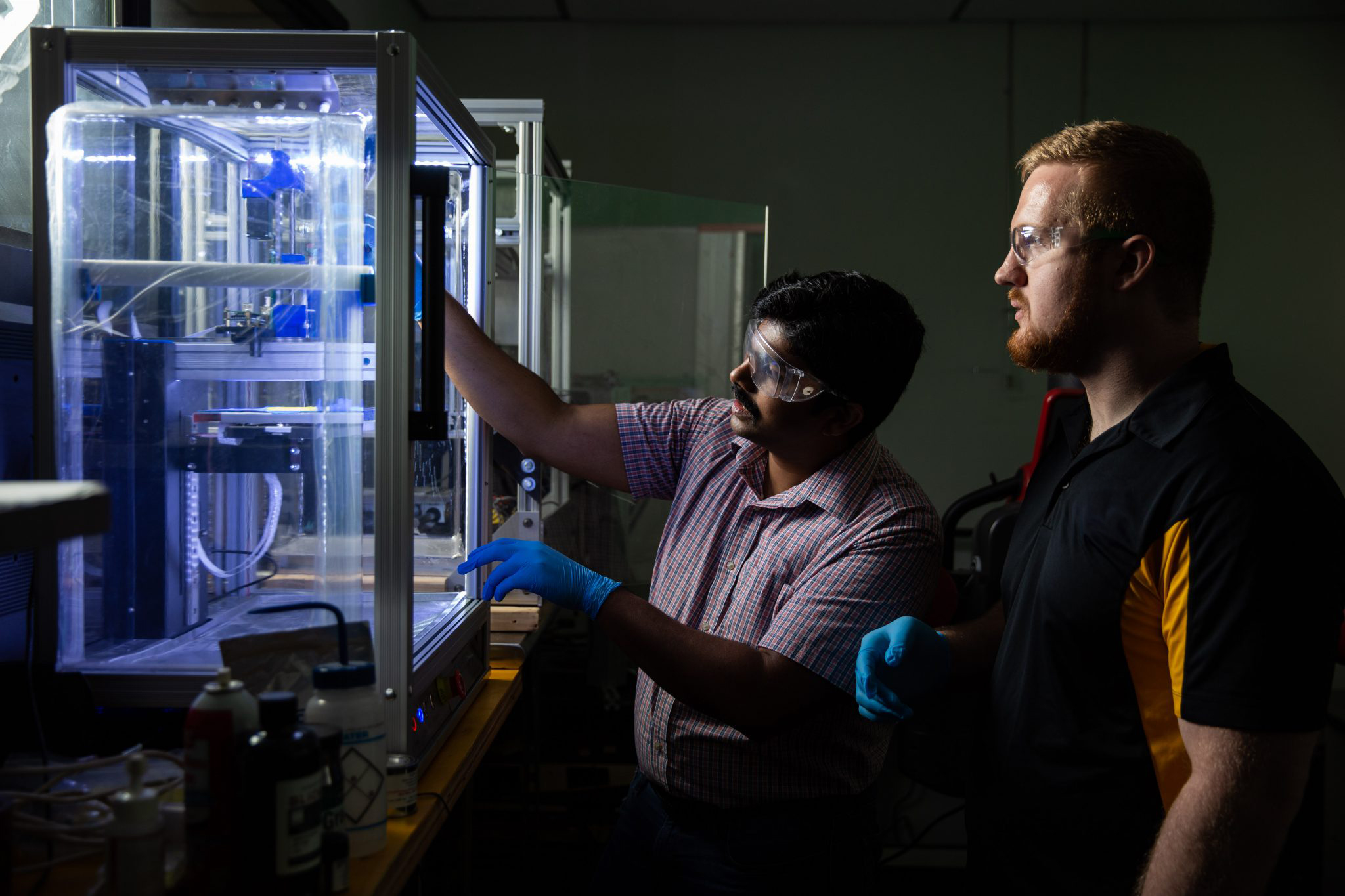

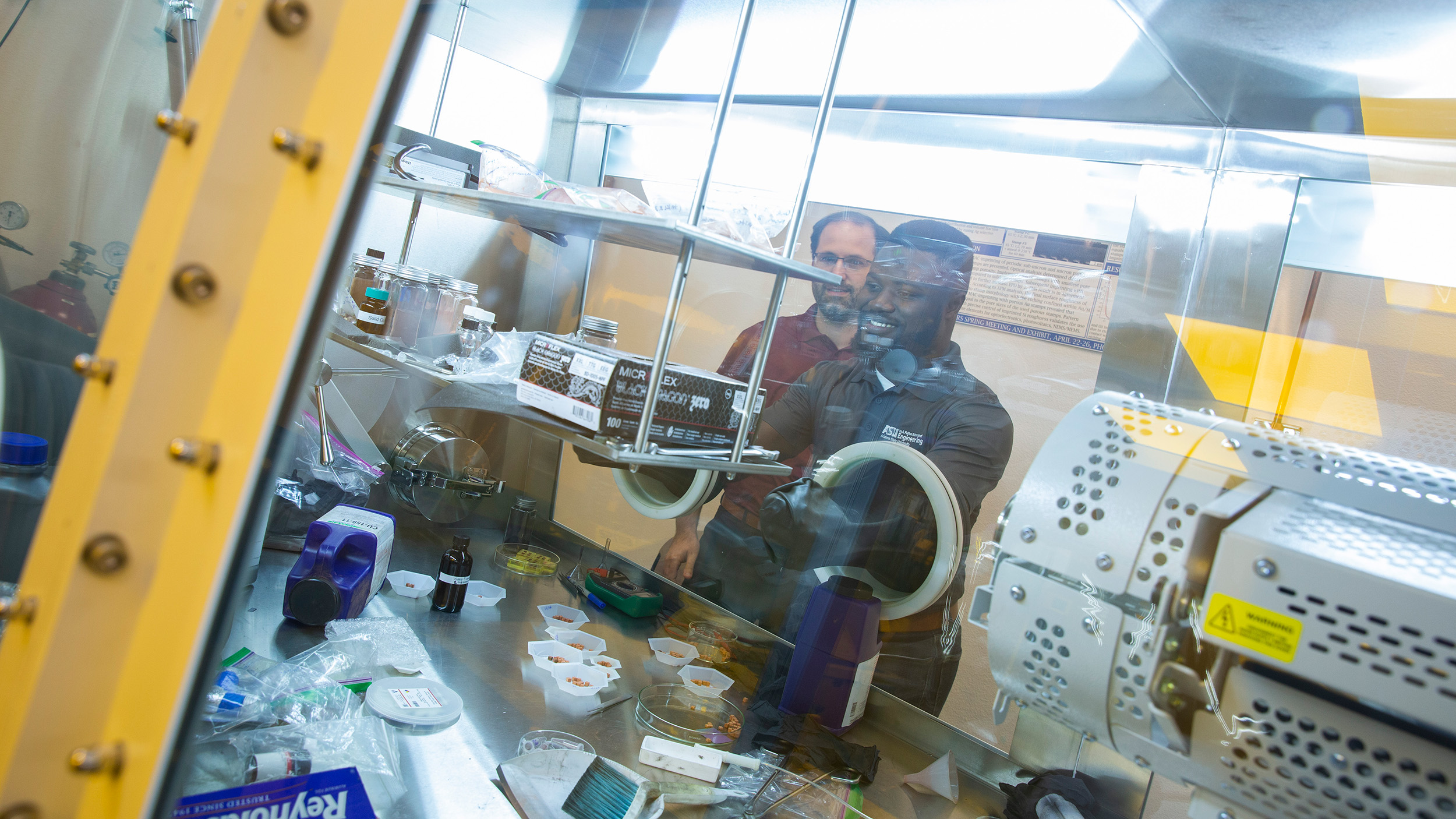

Students and faculty in the School of Manufacturing Systems and Networks have access to the latest manufacturing technologies for working on projects and conducting research.

MSN is located on ASU’s Polytechnic campus, which is home to both MSN and The Polytechnic School, and offers $2M in shared equipment and $5M in faculty lab resources.

Learn about our centers and see our specialized facilities and equipment.